If you've ever worked in a warehouse or distribution center, you know that every aspect of the operation needs to run like a well-oiled machine. For the effective and streamlined transportation of products. But sometimes when you are trying to load or unload the goods, You may face difficulties while doing this, as it can take a lot of time. In that case, you can look for platforms that provide loading and unloading at an affordable price.

So why are Loading Platform for Trucks so important? First and foremost, they improve safety for workers by minimizing the risk of injury from heavy lifting or awkward bending. Additionally, they allow for quicker and more efficient loading and unloading times, which can help increase productivity and decrease downtime. It is a raised structure that allows for trucks to be loaded and unloaded at a convenient height, without the need for manual lifting or lowering of heavy items.

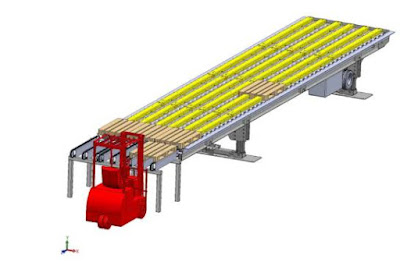

These platforms are typically made of durable materials such as concrete or metal and can be equipped with features such as dock levelers, safety rails, and adjustable height levels. But the benefits of loading platforms go beyond just safety and efficiency. They also offer versatility and adaptability to meet the needs of a wide range of industries and businesses. Loading platforms can be customized to accommodate various truck sizes and configurations, and can even be covered or enclosed to protect workers and goods from the elements.

In conclusion, Loading Platforms for Trucks are a critical component of warehouse and distribution center operations. They improve safety, efficiency, and versatility, making them an invaluable tool for businesses looking to streamline their logistics processes. By investing in quality platforms and taking care to maintain them properly. The companies can set themselves up for long-term success and growth.